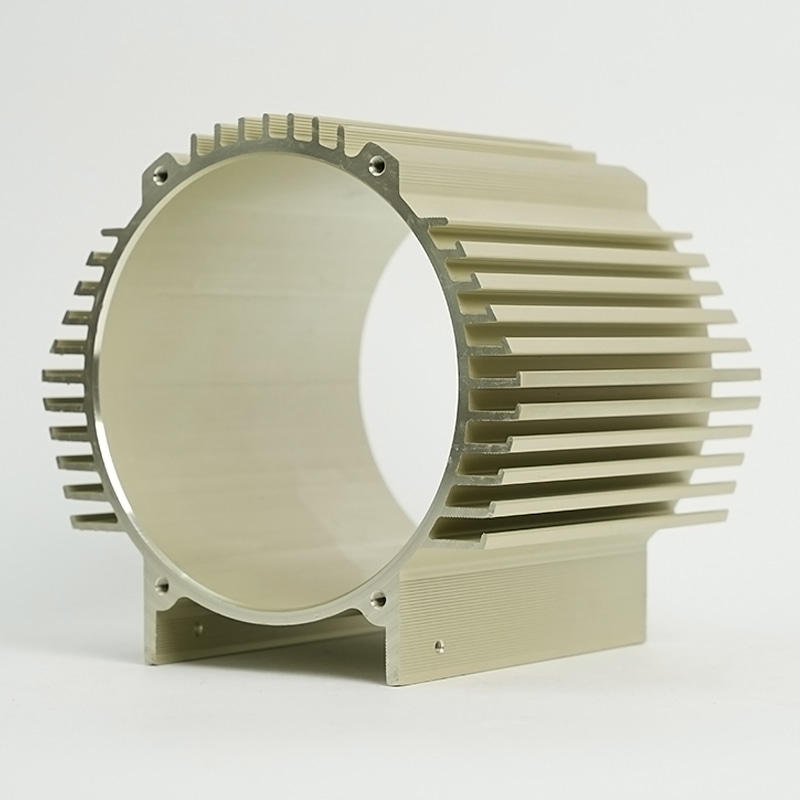

What Is a Micro Aluminum Gold Motor Shell?

- Definition and fundamental role in motor manufacturing

- Typical specifications: inner hole range from 46mm to 260mm

- Importance in motor efficiency, durability, and performance

Why Choose Industrial Micro Aluminum Gold Motor Shell Applications?

1. Heat Dissipation and Lightweight Advantage

| Feature | Aluminum Alloy Shell | Traditional Cast Iron |

| Weight | Lightweight (≈20% of cast iron) | Heavy |

| Heat Dissipation | High thermal conductivity | Lower thermal performance |

| Temperature Rise | Low | Higher |

| Manufacturing Efficiency | Fast, customizable | Slower, rigid |

2. Customization and Precision

- Supports a wide range of shapes and sizes

- Mold library with more than 600 variations

- Ellipticity control within 10s for superior precision

Key Benefits of Micro Aluminum Gold Motor Shell Heat Dissipation Benefits

- Improved motor lifespan due to efficient heat dispersion

- Reduced energy loss during continuous operation

- Enhanced performance in high-load or prolonged use conditions

How We Manufacture High Precision Micro Aluminum Gold Motor Shell Manufacturing

A. Mold Design and Versatility

- Multiple mold base coverage (from 71 to 160 bases)

- Low mold cost with high adaptability

- Custom length and design based on motor requirements

B. Quality Control and Certifications

- ISO9001 quality management system

- Environmental and surface treatment certifications

- Internal checks on dimension accuracy and finish

Choosing an ISO9001 Certified Micro Aluminum Gold Motor Shell Supplier

1. Production Capacity

- Large-scale manufacturing capability up to 5,000 sets daily

- Surface treatment options: oxidation and electrophoresis on-site

- Facility footprint of 16,000 m² supporting high-volume orders

2. After-Sales Support

- Technical support for customization queries

- Quality assurance and service follow-ups

- Long-term cooperation advantages for industrial clients

Frequently Asked Questions (FAQ)

Q1: What materials are used in a Micro Aluminum Gold Motor Shell?

- High-grade aluminum alloy with optimal thermal and mechanical properties.

Q2: Can sizes be customized?

- Yes, custom sizes and shapes are available with mold flexibility.

Q3: What industries use these shells?

- They are widely used in servo, water pump, air conditioning, and other motor applications.

Q4: Are quality standards guaranteed?

- Production follows ISO9001 certification standards for consistent quality.

Q5: How does heat dissipation improve motor performance?

- Efficient heat release lowers temperature rise, extending lifespan and reliability.

English

English Español

Español