Understanding the Fundamentals of Aluminum Motor Housings

The motor housing, often referred to as the frame or enclosure, is far more than a simple protective shell. It is a critical structural component that defines the motor's physical integrity, thermal performance, and overall efficiency. Among the various materials used for this purpose, aluminum has emerged as a premier choice for a vast range of applications, from miniature specialized motors to robust industrial drives. The shift towards aluminum motor housings is driven by a confluence of factors including the global push for energy efficiency, weight reduction in portable and automotive applications, and the need for superior thermal management in high-performance systems. This article delves deep into the world of aluminum motor housings, exploring their unique benefits, manufacturing nuances, and specific applications, while also providing insights into the technical considerations that engineers and procurement specialists must evaluate. As a leader in this specialized manufacturing sector, Jingjiang Hetai Motor Parts Manufacturing Co., Ltd. has been at the forefront of producing high-precision aluminum alloy housings since 2007, serving a diverse global clientele with a portfolio of over 600 different shell molds and a commitment to quality certified by ISO9001 standards.

Five Key Advantages of Choosing Aluminum for Motor Housings

The selection of aluminum for motor housings is not arbitrary; it is a calculated decision based on a set of compelling material advantages that directly impact motor performance and lifecycle costs. These benefits collectively address some of the most pressing challenges in motor design and application.

Superior Thermal Conductivity and Heat Dissipation

One of the most significant advantages of aluminum is its excellent thermal conductivity. Heat is the enemy of electric motor efficiency and longevity. Excessive temperatures can degrade insulation, demagnetize permanent magnets, and increase winding resistance, leading to premature failure. Aluminum housings act as an effective heat sink, rapidly transferring heat generated from the stator and rotor windings to the external environment. For instance, aluminum motor housing for water pump applications is particularly critical because these motors often operate continuously in demanding environments. The fast heat dissipation capability of aluminum ensures that the motor maintains a lower temperature rise, which directly translates to improved operational reliability and extended service life. Compared to cast iron, aluminum can dissipate heat several times faster, making it indispensable for applications where cooling is a challenge.

Significant Weight Reduction and Improved Power-to-Weight Ratio

The density of aluminum is approximately one-third that of steel or cast iron. This dramatic difference results in a housing that is remarkably lightweight. A direct comparison reveals that an aluminum alloy tensile shell typically weighs only about one-fifth of a cast iron shell of the same dimensions. This weight saving is paramount in applications such as portable tools, automotive auxiliaries, robotics, and aerospace systems, where every gram counts. The reduced weight contributes to lower inertial loads, potentially faster acceleration in servo applications, and overall energy savings in systems where the motor is part of a moving mass. This inherent lightness, combined with adequate strength, gives aluminum a superior power-to-weight ratio, a key metric in modern electromechanical design.

Enhanced Corrosion Resistance and Surface Finish Options

Aluminum naturally forms a protective oxide layer when exposed to atmosphere, which provides inherent corrosion resistance. This property can be significantly enhanced through various surface treatments. Manufacturers like Jingjiang Hetai Motor Parts Manufacturing Co., Ltd. possess independent oxidation and electrophoresis qualifications, allowing them to offer housings with specialized finishes. These treatments not only improve corrosion resistance for use in humid or chemically aggressive environments but also provide aesthetic appeal and additional surface hardness. Anodizing, for example, can create a hard, wear-resistant layer in various colors. This is especially valuable for consumer-facing products or motors used in food processing or marine applications.

High Versatility in Manufacturing and Design Flexibility

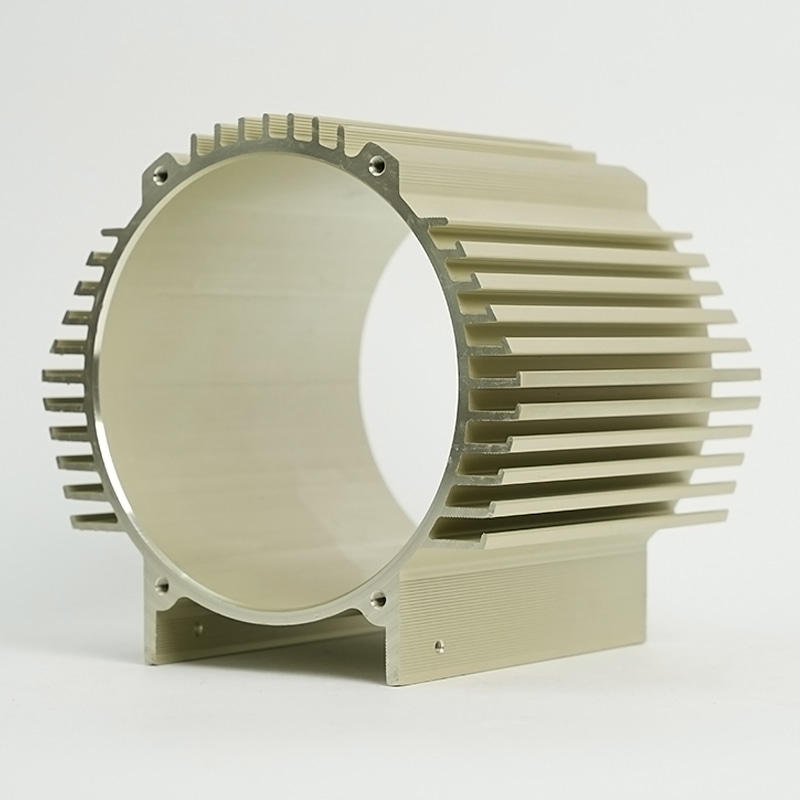

Aluminum is exceptionally versatile in terms of manufacturing processes. It can be easily extruded, die-cast, drawn, and machined, allowing for great design freedom and cost-effective production of complex shapes. The extrusion process, in particular, enables the creation of intricate cooling fin designs that maximize surface area for heat dissipation without significant additional cost. This versatility supports high-volume production runs with consistent quality. As evidenced by the capabilities at Hetai, where a single pair of molds can produce housings for different frame lengths (e.g., 132M and 132L), the tooling cost is lower and the universality is strong. Designers can customize lengths arbitrarily and utilize pre-finished internal holes, eliminating costly machining steps.

Cost-Effectiveness in High-Volume Production

While the raw material cost of aluminum can be higher than cast iron, the total manufactured cost often favors aluminum in medium to high volumes. The reasons are multifaceted: lower machining costs due to the material's softer nature, reduced energy consumption during processing, faster cycle times in casting or extrusion, and savings in secondary operations like finishing. Furthermore, the weight reduction leads to lower shipping and handling costs. The overall lifecycle cost benefit, considering improved motor efficiency and longevity, makes aluminum a financially sound choice for many projects.

Addressing Specific Applications with Tailored Solutions

The generic benefits of aluminum motor housings manifest uniquely across different industries and motor types. Understanding these specific applications helps in selecting the right housing characteristics.

Housings for Micro and Special Purpose Motors

The domain of micro and special motors demands precision, reliability, and often, customization. Aluminum is the material of choice here due to its excellent machinability to tight tolerances and its ability to be formed into small, complex shapes. Jingjiang Hetai Motor Parts Manufacturing Co., Ltd. specializes in this area, producing shells with inner holes ranging from 46mm to 260mm for a wide array of applications. Key sectors include:

- Reducer Motors: Aluminum housings contribute to compact and lightweight gearmotor assemblies.

- Sewing Machine Motors: Low weight and quiet operation are essential, both enhanced by aluminum.

- Servo and Stepper Motors: High responsiveness requires low inertia, which is aided by lightweight aluminum frames. Optimal aluminum servo motor housing design focuses on stiffness-to-weight ratio and precise mounting interfaces to ensure accurate positioning.

- Office Automation Equipment: Motors in printers, scanners, and copiers benefit from the quiet, efficient cooling of aluminum.

The company's vast library of over 600 mold specifications directly supports this need for variety and rapid customization in the special motor market.

The Critical Role in Automotive and Traction Applications

The automotive industry's electrification is a major driver for advanced aluminum motor housings. In electric vehicles (EVs), hybrid systems, and traditional automotive auxiliaries (like pumps, fans, and window lift motors), aluminum housings are indispensable. The primary drivers are weight reduction to extend vehicle range and efficient thermal management to handle high power densities. An aluminum motor housing for electric vehicle is engineered not just as a container but as an integrated thermal management component, often featuring complex internal coolant passages. The housing must also exhibit high structural integrity to withstand vibrations and mechanical loads over the vehicle's lifetime. The shift from cast iron to aluminum in this sector represents a significant step towards meeting stringent emissions and efficiency regulations.

Demanding Environments: Pumps, Compressors, and HVAC Systems

Motors operating in pumps, compressors, and Heating, Ventilation, and Air Conditioning (HVAC) systems face unique challenges: continuous duty cycles, exposure to elements, and the critical need for reliability. For a aluminum motor housing for water pump, the material's corrosion resistance is a key asset, especially for submersible or outdoor pumps. In HVAC systems, where fan and compressor motors are central to operation, the superior heat dissipation of aluminum ensures consistent performance and prevents overheating during peak summer loads. The ability to form integrated cooling fins directly into the housing design allows for more compact and efficient motor packages compared to older designs that relied on separate fan shrouds or bulky castings.

Material and Manufacturing Process Deep Dive

The performance of an aluminum motor housing is deeply influenced by the specific alloy chosen and the manufacturing process employed. These choices determine the final product's mechanical properties, dimensional accuracy, and cost.

Common Aluminum Alloys and Their Properties

Not all aluminum is created equal. Different alloys are tailored for different manufacturing processes and performance requirements.

| Alloy Series | Key Characteristics | Typical Manufacturing Process | Ideal For |

|---|---|---|---|

| 1xxx (e.g., 1050, 1100) | High purity, excellent corrosion resistance and thermal/electrical conductivity, lower strength. | Deep drawing, spinning. | Housings where maximum heat dissipation is critical and mechanical loads are low. |

| 3xxx (e.g., 3003) | Good formability, moderate strength, excellent corrosion resistance. | Drawing, extrusion. | General-purpose housings, enclosures for consumer appliance motors. |

| 5xxx (e.g., 5052, 5083) | Good strength, excellent corrosion resistance (especially to salt water), weldable. | Drawing, machining. | Marine, automotive, and other high-corrosion risk environments. |

| 6xxx (e.g., 6061, 6063) | Excellent all-rounders. Good strength, corrosion resistance, machinability, and weldability. Can be heat-treated. | Extrusion (most common), machining. | The most common choice for extruded motor housings. Used in industrial motors, servo motors, etc. |

| A380, ADC12 | Die-casting specific alloys. Good fluidity, strength, and dimensional stability. | High-pressure die casting. | High-volume production of complex-shaped housings where intricate details are needed. |

Selecting the right alloy involves balancing factors like required tensile strength, corrosion resistance, thermal performance, and manufacturability. For extrusion-based profiles common in many industrial motors, the 6xxx series, particularly 6063, is a prevalent choice due to its optimal balance of properties.

Extrusion vs. Die Casting: A Comparative Analysis

The two primary mass-production methods for aluminum motor housings are extrusion and die casting. The choice between them significantly impacts the design, performance, and economics of the final product.

Extrusion involves forcing heated aluminum billet through a shaped die to create a continuous profile with a constant cross-section. This profile is then cut to length and machined as needed. Die casting, on the other hand, involves injecting molten aluminum under high pressure into a steel mold cavity to form a near-net-shape part.

| Parameter | Extrusion | Die Casting |

|---|---|---|

| Design Flexibility | Excellent for creating complex cross-sections with integrated cooling fins. Limited to constant cross-section along length. | Exceptional for complex 3D geometries, including bosses, ribs, and mounting points in all dimensions. |

| Mechanical Properties | Generally superior strength and better grain structure due to the working of the metal. Good for structural parts. | Properties are good but can have porosity. Heat treatment options may be more limited compared to wrought alloys. |

| Dimensional Accuracy & Surface Finish | Good dimensional accuracy on the profile. Excellent surface finish often requiring minimal post-processing. | High dimensional accuracy and ability to produce very fine details. Surface finish is good but may show minor casting marks. |

| Tooling Cost and Lead Time | Moderate. Die costs are lower than casting molds. Well-suited for custom lengths from standard profiles. | High. Mold costs are significant due to complexity and required steel strength. |

| Economic Production Volume | Cost-effective for medium to high volumes, especially when using standard profiles. Low waste. | Most cost-effective for very high volumes where the high mold cost is amortized over millions of parts. |

| Typical Applications | Industrial motor frames, servo motor housings, housings with long continuous cooling fins. | Small appliance motors, automotive auxiliary motor housings, intricate pump housings. |

Many manufacturers, including Jingjiang Hetai, master both processes to offer the optimal solution. Their successful development of the YX3 profile case series from 71 to 160 bases demonstrates expertise in extrusion, while their ability to handle over 600 mold types indicates deep capability in die casting and tooling.

Precision Machining and Quality Control

Post-forming operations are crucial for ensuring the housing meets precise functional requirements. Key machining operations include boring the inner diameter for stator fit, facing end brackets mounting surfaces, drilling and tapping mounting holes, and machining any special features. The precision of these operations directly affects motor performance. For example, controlling the inner hole ellipticity (out-of-roundness) is critical for maintaining a uniform air gap between the stator and rotor. Jingjiang Hetai maintains tight control, keeping ellipticity within 10 seconds of arc (a very precise tolerance), which minimizes vibration and magnetic noise. Quality control is enforced through a system certified to ISO9001, ensuring consistency and reliability for every batch produced. This involves rigorous inspection of dimensions, material certificates, surface finish, and performance in sample assemblies.

Key Design Considerations and Technical Specifications

Designing or specifying an aluminum motor housing requires careful attention to several interrelated technical parameters. Overlooking any one can compromise the final motor assembly.

Thermal Management and Heat Sink Integration

The primary design advantage of aluminum is leveraged through intelligent thermal design. The housing must be viewed as part of the motor's cooling system. Key strategies include:

- Integrated Cooling Fins: Extruded or cast fins increase the surface area for convective heat transfer. The fin geometry (height, thickness, spacing) is optimized based on the available airflow (natural convection or forced by a fan).

- Material Thickness and Thermal Path: Ensuring a robust thermal path from the stator laminations to the outer fins is vital. This often involves designing for good mechanical contact between the stator and housing, sometimes using thermal interface compounds or shrink-fit processes.

- Application-Specific Design: An aluminum motor housing for high temperature applications might incorporate larger fins, different alloy selection (for high-temperature strength), or even provisions for liquid cooling jackets. The design must account for thermal expansion to prevent stress or distortion during operation.

Structural Integrity, Stiffness, and Vibration Damping

While lightweight, the housing must be stiff enough to maintain critical alignments and dampen vibrations generated by electromagnetic forces and rotor imbalance. Design factors include:

- Wall Thickness and Ribbing: Strategic placement of ribs or increased wall thickness in high-stress areas (like mounting feet) enhances stiffness without adding excessive weight. For an aluminum servo motor housing design, maximizing torsional stiffness is particularly important to maintain dynamic response and positioning accuracy.

- Natural Frequency: The housing's natural frequency should be designed to avoid resonance with the motor's operating speed and its harmonics, which can lead to excessive noise and fatigue failure.

- Mounting Interface Design: The design of feet, flanges, or through-bolt patterns must ensure secure attachment to the driven machine, distributing loads evenly to prevent distortion.

Electromagnetic Shielding and IP Ratings

Beyond thermal and mechanical functions, the housing often plays a role in electromagnetic compatibility (EMC) and environmental protection.

- EMI/RFI Shielding: Aluminum, being a conductor, provides inherent shielding against electric fields. For motors that are sensitive to or generators of electromagnetic interference, the housing design must ensure electrical continuity, often requiring careful attention to joint design between housing parts and covers.

- Ingress Protection (IP): The housing design dictates the motor's protection against dust and water. Achieving higher IP ratings (like IP65 or IP67) involves designing precise sealing grooves for gaskets, optimizing joint surfaces, and specifying appropriate seals. This is non-negotiable for aluminum motor housing for water pump or outdoor applications.

Future Trends and Industry Outlook

The future of aluminum motor housings is intertwined with broader trends in electrification, material science, and digital manufacturing. As industries push for higher efficiency and power density, the demands on the motor housing will intensify.

Lightweighting and Integration for Advanced Mobility

The trend towards electric and hybrid vehicles will continue to drive innovation. Future aluminum motor housing for electric vehicle designs will likely see deeper integration. We can expect housings that combine structural, thermal, and electrical functions into single, highly optimized components, potentially manufactured using advanced techniques like additive manufacturing (3D printing) for prototyping or low-volume complex parts. The pursuit of weight reduction will also lead to exploration of new aluminum alloys and composite materials that offer even better strength-to-weight ratios.

Advanced Manufacturing and Digitalization

Industry 4.0 concepts are permeating manufacturing. Smart factories will leverage real-time data from the production floor to optimize the extrusion, casting, and machining processes for aluminum housings, ensuring zero-defect production. Digital twins of housing designs will simulate thermal, structural, and fluid dynamics performance before a single part is made, accelerating development cycles. This digital thread, from design to finished product, will enable mass customization—producing highly tailored housings cost-effectively, much like the custom-length capability already offered by manufacturers using extrusion.

Sustainability and Circular Economy

Aluminum's recyclability is a massive advantage in an increasingly sustainability-conscious world. The energy required to recycle aluminum is only about 5% of that needed for primary production. This makes aluminum motor housings a green choice over their lifecycle. Manufacturers and end-users will increasingly prioritize the use of recycled aluminum content and design housings for easy disassembly and recycling at end-of-life. This aligns with global circular economy principles and can contribute to greener product certifications.

In conclusion, the aluminum motor housing is a sophisticated component that sits at the intersection of material science, thermal engineering, precision manufacturing, and application-specific design. Its advantages in weight, thermal performance, and versatility make it a dominant choice for the present and future of motor technology. Companies with deep expertise, a comprehensive manufacturing toolkit—like Jingjiang Hetai Motor Parts Manufacturing Co., Ltd. with its extensive mold library and surface treatment capabilities—and a commitment to precision and quality are well-positioned to partner with innovators across industries to power the next generation of efficient and reliable motor-driven systems.

English

English Español

Español