Introduction to Heat Sink Housing

What is a Heat Sink Housing?

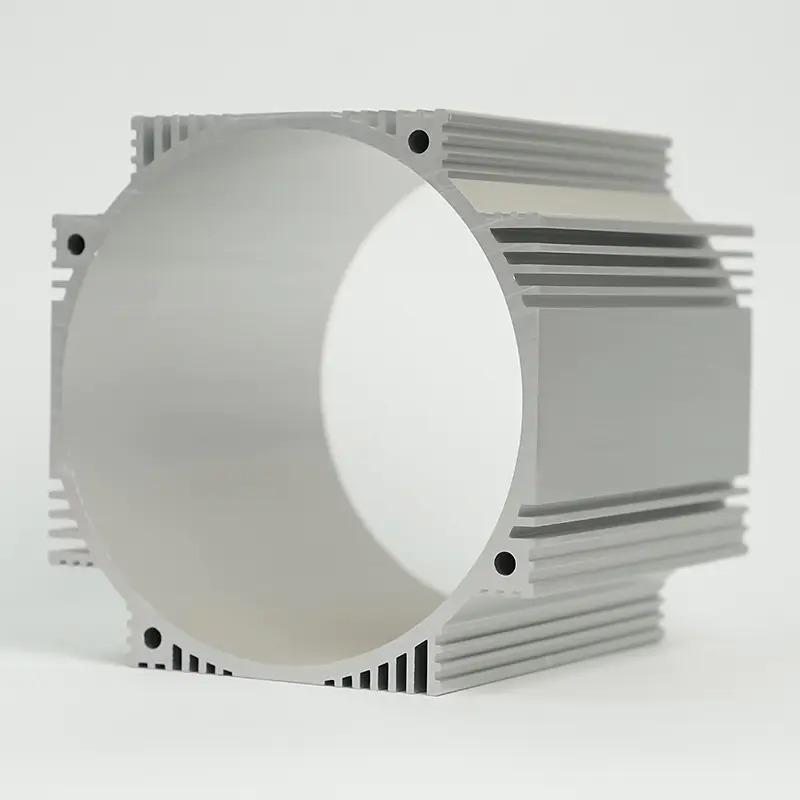

A Heat Sink Housing is a critical component used in electronic and industrial devices to manage and dissipate excess heat. By transferring thermal energy away from sensitive parts, it helps prevent overheating and ensures long-term reliability. The housing not only enhances cooling efficiency but also provides structural protection. Modern applications demand housings that are compact, durable, and capable of handling high-performance requirements. With the growing need for energy-efficient solutions, the design and customization of heat sink housings have become increasingly important. Selecting the right housing can significantly impact the stability, performance, and overall lifespan of devices.

- Provides mechanical support and thermal management

- Ensures safe operation of electronics under high loads

- Improves device efficiency and reduces energy waste

Applications Across Industries

The versatility of Heat Sink Housing makes it suitable for a wide range of industries. From lighting to power distribution, its role in maintaining temperature stability is essential. In Custom Heat Sink Housing for LED Lighting Applications, housings ensure high brightness and longer operational life. Similarly, Aluminum Heat Sink Housing for Power Electronics provides stability for high-power systems, while Durable Heat Sink Housing for Industrial Equipment guarantees safe operation in demanding environments. Compact designs are also crucial in consumer electronics, where space-saving and efficiency are key. Each sector benefits from unique design considerations that enhance device performance and reduce downtime.

- LED lighting systems

- High-power electronic devices

- Heavy-duty industrial machines

- Compact consumer electronics

Key Features of Efficient Heat Sink Housing

Material Selection and Durability

Material choice is one of the most critical factors in designing Heat Sink Housing. Metals like aluminum are widely used because of their excellent thermal conductivity and lightweight properties. In Aluminum Heat Sink Housing for Power Electronics, the use of aluminum ensures effective heat transfer while maintaining mechanical strength. Durability is equally important, especially in Durable Heat Sink Housing for Industrial Equipment, where exposure to high heat and harsh conditions requires robust materials. Proper surface treatments can extend the lifespan and improve the thermal efficiency of housings, ensuring stable operation even in demanding scenarios.

- Aluminum for superior conductivity

- Surface treatments for corrosion resistance

- Durability for long-term applications

| Material | Conductivity | Durability |

| Aluminum | High | Medium to High |

| Copper | Very High | High |

| Steel | Low | Very High |

Design Considerations

Design plays a central role in maximizing cooling efficiency. Compact designs, like those in Compact Heat Sink Housing for Consumer Electronics, save space while ensuring effective heat dissipation. Integration with active or passive cooling systems also enhances performance. The structural design must balance lightweight requirements with robustness to handle demanding applications. Advanced computational modeling allows manufacturers to simulate airflow and heat dissipation before production, ensuring higher efficiency. An optimized design not only improves cooling but also enhances the overall performance and reliability of devices in real-world applications.

- Compact and lightweight form factors

- Integration with cooling systems

- Optimized airflow designs

| Design Type | Advantages | Applications |

| Compact Housing | Saves space | Consumer electronics |

| Heavy-Duty Housing | Durability | Industrial equipment |

| Integrated Housing | Higher thermal control | Power electronics |

Custom Heat Sink Housing Solutions

For LED Lighting Applications

Custom Heat Sink Housing for LED Lighting Applications ensures that LEDs remain cool even under continuous operation. Effective housings prevent brightness degradation and extend the service life of lighting systems. Since LEDs are sensitive to temperature fluctuations, high-performance housings are designed with optimized fin shapes and surfaces to maximize heat dissipation. This results in improved energy efficiency and consistent illumination quality. By using lightweight yet durable materials, housings also support versatile lighting installations in residential, commercial, and industrial environments.

- Improves LED efficiency and brightness

- Ensures longer product life

- Supports versatile lighting systems

For Power Electronics

High-power devices require robust thermal management solutions. Aluminum Heat Sink Housing for Power Electronics offers a perfect balance of conductivity, strength, and weight. These housings are engineered to handle large thermal loads while ensuring that systems remain stable under continuous operation. Properly designed housings can also integrate with cooling systems, further enhancing thermal performance. The use of aluminum reduces overall system weight without compromising durability, making it a preferred material in advanced electronic systems.

- Handles high thermal loads effectively

- Lightweight and strong aluminum construction

- Supports stability under heavy use

For Industrial Equipment

In heavy-duty environments, Durable Heat Sink Housing for Industrial Equipment ensures reliable performance under extreme conditions. Industrial machinery often generates high amounts of heat during continuous operation, which requires rugged housings capable of withstanding thermal and mechanical stress. Durable housings not only protect electronic components but also reduce downtime and maintenance costs. Using advanced surface treatments further improves resistance against corrosion and wear, ensuring long-term reliability even in challenging conditions.

- Reliable in high-temperature environments

- Minimizes maintenance costs

- Enhances safety and stability

Advanced Design Techniques

Optimizing Thermal Performance

Achieving maximum thermal efficiency requires careful design optimization. Fin density, thickness, and orientation directly influence how effectively a Heat Sink Housing dissipates heat. Surface treatments such as anodizing can enhance thermal transfer by improving emissivity. Engineers also use simulation tools to test airflow, heat transfer, and stress points before physical production, ensuring better results. By applying these techniques, housings achieve superior cooling performance, energy efficiency, and reliability across multiple applications.

- Optimized fin density and geometry

- Surface treatments for improved heat transfer

- Simulation testing before production

Compact and Efficient Designs

Modern devices demand space-saving solutions. Compact Heat Sink Housing for Consumer Electronics is designed to provide effective cooling in minimal space. These housings combine lightweight structures with efficient airflow channels, ensuring performance without sacrificing form factor. Compact housings are widely used in smartphones, laptops, and other portable devices where thermal management is critical. Advanced design techniques ensure that even small housings can perform effectively in demanding applications.

- Space-efficient designs for compact devices

- Lightweight structures for portability

- Optimized airflow channels for cooling

Designing an efficient Heat Sink Housing is crucial for achieving maximum cooling performance across industries. Whether for LED lighting applications, power electronics, industrial equipment, or consumer electronics, the right housing ensures device stability and reliability. Advanced materials, smart design techniques, and customized solutions all contribute to better thermal management. As demand for compact, durable, and energy-efficient devices grows, the importance of optimized housings will only increase in the future.

- Improves cooling and stability

- Extends device lifespan

- Supports innovation in electronics and industry

FAQ

What materials are best for Heat Sink Housing?

Aluminum is the most commonly used material in Heat Sink Housing due to its excellent balance of thermal conductivity, durability, and cost efficiency. Copper provides higher conductivity but is heavier and more expensive, while steel offers durability but lacks effective thermal transfer.

How does Heat Sink Housing improve LED lighting performance?

In Custom Heat Sink Housing for LED Lighting Applications, proper heat dissipation prevents overheating, which maintains brightness and extends the operational life of LEDs. Without adequate cooling, LEDs may lose efficiency and fail prematurely.

Why is aluminum preferred in Power Electronics Heat Sink Housing?

Aluminum Heat Sink Housing for Power Electronics is preferred because it combines high thermal conductivity with lightweight strength, ensuring effective cooling without adding excessive weight to electronic systems.

What makes Heat Sink Housing durable for industrial equipment?

Durable Heat Sink Housing for Industrial Equipment is built with robust materials and protective coatings to withstand high heat, vibration, and environmental challenges, reducing downtime and maintenance costs in demanding environments.

Can compact Heat Sink Housing provide effective cooling?

Yes, Compact Heat Sink Housing for Consumer Electronics is designed with advanced airflow channels and efficient fin structures, allowing small devices like laptops and smartphones to maintain stable temperatures without compromising performance.

English

English Español

Español