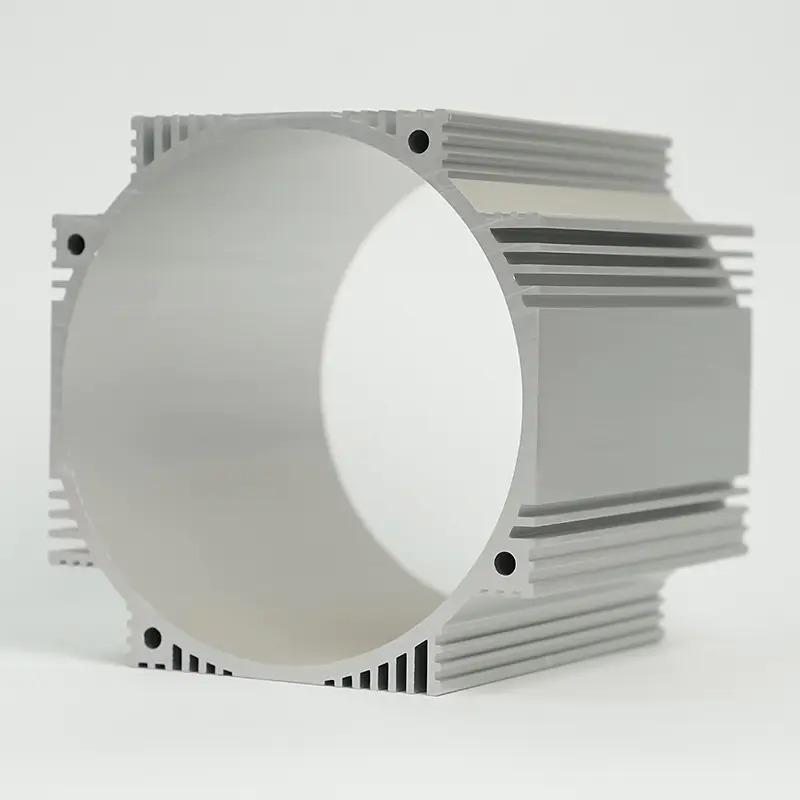

Introduction to Micro Aluminum Gold Motor Shells

Micro aluminum gold motor shells are specialized enclosures designed to house miniature motors, particularly those operating at high speeds. These shells are crafted from a combination of aluminum and a gold coating, offering a unique blend of properties that enhance motor performance and longevity.

The selection of materials for motor housings is crucial, as it directly impacts the motor's efficiency, heat dissipation, and overall durability. Aluminum is favored for its lightweight and thermal properties, while gold coating is applied to improve electrical conductivity and resistance to wear.

Advantages of Aluminum in Motor Shells

Aluminum is a preferred material for micro motor housings due to several key advantages:

- Lightweight properties: Aluminum's low density reduces the overall weight of the motor, making it ideal for applications where weight is a critical factor.

- Thermal conductivity: Aluminum efficiently dissipates heat, preventing overheating and ensuring stable motor performance.

- Corrosion resistance: The natural oxide layer on aluminum provides protection against corrosion, extending the motor's lifespan.

The Role of Gold Coating in Motor Shells

Applying a gold coating to micro motor shells offers several benefits:

- Enhanced electrical conductivity: Gold's excellent conductivity ensures efficient power transmission within the motor.

- Improved durability and wear resistance: The gold layer provides a hard surface that resists abrasion and wear, maintaining motor performance over time.

- Aesthetic and branding benefits: The gold finish adds a premium appearance, which can be advantageous for branding and marketing purposes.

Applications of Micro Aluminum Gold Motor Shells

Micro aluminum gold motor shells are utilized across various industries:

- Consumer electronics: Used in devices like smartphones, drones, and wearable technology, where compact size and high performance are essential.

- Automotive industry: Employed in electric vehicles and precision components, benefiting from the lightweight and conductive properties.

- Aerospace and robotics: Critical in applications requiring high-speed motors with reliable performance and durability.

Comparing Micro Aluminum Gold Motor Shells with Other Materials

When compared to other materials, micro aluminum gold motor shells offer distinct advantages:

| Material | Weight | Thermal Conductivity | Electrical Conductivity | Corrosion Resistance |

| Aluminum | Low | High | Moderate | High |

| Steel | High | Moderate | Low | Moderate |

| Gold-coated Aluminum | Low | High | Very High | Very High |

FAQ

What are the benefits of using aluminum in motor shells?

Aluminum's lightweight nature reduces the overall weight of the motor, enhancing efficiency and enabling use in compact applications. Its excellent thermal conductivity aids in heat dissipation, preventing overheating and ensuring consistent performance. Additionally, aluminum's natural corrosion resistance extends the motor's operational life.

Why is gold coating applied to micro motor housings?

Gold coating enhances the electrical conductivity of the motor shell, ensuring efficient power transmission. It also provides a durable surface that resists wear and corrosion, maintaining the motor's performance over time. Moreover, the gold finish adds a premium aesthetic, which can be beneficial for branding purposes.

In which industries are micro aluminum gold motor shells commonly used?

These motor shells are prevalent in industries such as consumer electronics, automotive, aerospace, and robotics. They are particularly suited for applications requiring compact size, high-speed operation, and reliable performance under demanding conditions.

English

English Español

Español