In the demanding world of material handling and industrial machinery, the performance and reliability of core components are paramount. Among these, the motor housing plays a critical role in protecting and enhancing the electric drive system. For forklifts and other heavy-duty equipment, the forklift extruded motor housing has become a preferred engineering solution. This comprehensive guide delves deep into the world of extruded aluminum motor housings, exploring their manufacturing process, key benefits, and specific applications in material handling, providing essential information for engineers, purchasers, and industry professionals.

What is a Forklift Extruded Motor Housing?

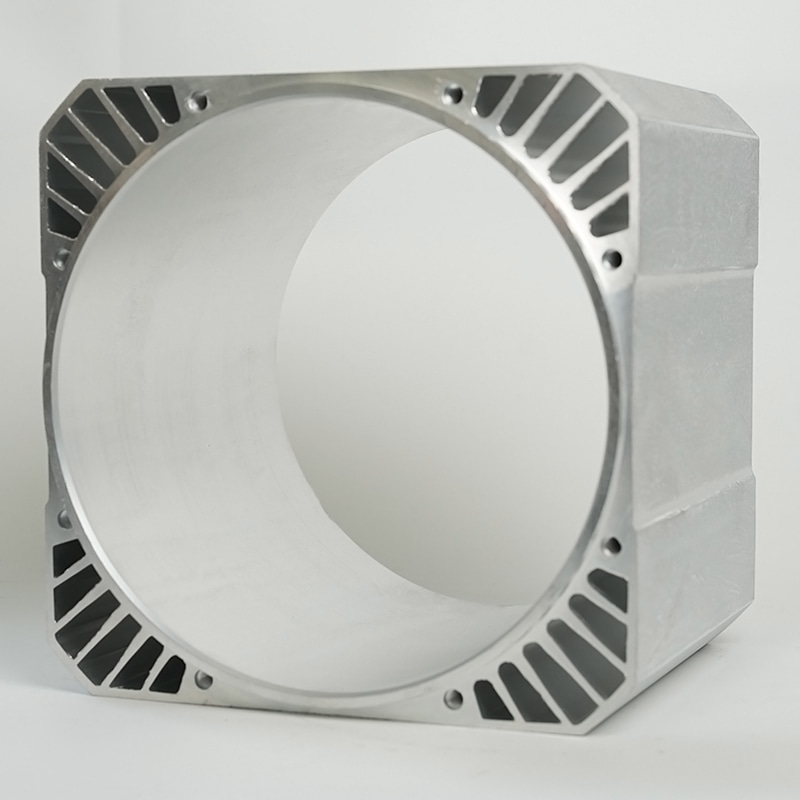

An extruded motor housing is a cylindrical or shaped enclosure for an electric motor, manufactured through a process called aluminum extrusion. Unlike cast housings, which are formed by pouring molten metal into a mold, extrusion involves forcing heated aluminum alloy through a precision die to create a continuous profile with a consistent cross-section. This profile is then cut to length and machined to precise specifications.

For forklift applications, these housings are engineered to withstand rigorous operational conditions, including vibration, thermal cycling, and mechanical stress. The inherent properties of aluminum, combined with the extrusion process, make it an ideal choice for the modern warehouse and logistics environment.

The Extrusion Manufacturing Process: Precision from Start to Finish

At Jingjiang Hetai Motor Parts Manufacturing Co., Ltd., the production of a high-quality forklift extruded motor housing involves a meticulous, multi-step process that ensures dimensional accuracy and structural integrity.

Step-by-Step Production

- Billet Preparation: High-grade aluminum alloy billets are heated to a specific temperature to become malleable.

- Extrusion: The softened billet is pushed through a custom-designed steel die using a hydraulic ram, forming the housing's precise cross-sectional profile.

- Cooling and Straightening: The elongated profile is cooled and then straightened to eliminate any warping.

- Cutting to Length: The continuous profile is cut into specified housing lengths.

- Heat Treatment (Aging): The housings undergo heat treatment to enhance their mechanical strength and stability.

- Precision Machining: Critical features such as mounting holes, end connections, and the inner bore are machined with high precision. Hetai's capability to control inner hole ellipticity within 10 seconds is a testament to this precision.

- Surface Treatment: The housing receives surface finishing, such as anodizing or electrophoresis, to improve corrosion resistance, appearance, and thermal dissipation.

Key Advantages of Extruded Aluminum Motor Housings

Choosing an extruded aluminum housing over traditional cast iron or cast aluminum offers a multitude of benefits that directly impact performance and total cost of ownership.

Performance and Operational Benefits

Superior Thermal Management

- The excellent thermal conductivity of aluminum allows for rapid heat dissipation from the motor windings.

- This leads to a lower operating temperature rise, increasing motor efficiency and extending insulation life.

Significant Weight Reduction

- Aluminum housings are exceptionally light. A stretch-formed aluminum alloy shell weighs only about one-fifth of a comparable cast iron housing.

- This weight saving directly contributes to higher energy efficiency and greater payload capacity for the forklift.

High Strength and Durability

- Modern aluminum alloys used in extrusion offer an excellent strength-to-weight ratio.

- They resist corrosion and can withstand the vibrations and shocks common in material handling [1].

Economic and Manufacturing Advantages

Cost-Effective Tooling and Flexibility

- Extruded motor housing mold costs are significantly lower than for complex casting molds.

- The process offers strong versatility; for instance, a single die can produce housings for different frame lengths (e.g., 132M and 132L), with length customized as needed.

Production Efficiency

- Extrusion allows for continuous, high-volume production. Hetai, for example, has a class output of up to 5,000 sets.

- Secondary machining is minimized, especially since internal holes often require no cutting, saving labor and time.

Critical Considerations for Selecting a Forklift Motor Housing

Selecting the right housing requires evaluating several technical and operational factors to ensure optimal compatibility and performance.

Material and Design Specifications

- Alloy Grade: The specific aluminum alloy (e.g., 6061, 6063) impacts strength, machinability, and thermal properties.

- Dimensional Tolerances: Precision in inner diameter (bore ellipticity), outer diameter, and length is crucial for proper motor assembly and alignment.

- Heat Dissipation Requirements: The design must provide adequate surface area and thermal pathway for the motor's heat load.

Comparative Analysis: Extruded Aluminum vs. Traditional Cast Housings

When comparing housings for a forklift drive motor enclosure, the differences between extruded aluminum and traditional cast (iron or aluminum) are pronounced. The table below highlights these key distinctions.

The following table compares the key attributes of extruded aluminum housings versus traditional cast housings, providing a clear overview for decision-making.

| Feature | Extruded Aluminum Housing | Traditional Cast Housing |

|---|---|---|

| Weight | Very Light (≈1/5 of cast iron) | Heavy |

| Thermal Conductivity | Excellent | Poor (Iron) / Moderate (Cast Al) |

| Production Lead Time | Generally Shorter | Generally Longer |

| Tooling (Mold) Cost | Lower | Substantially Higher |

| Design Flexibility | High for profile; length is easily customized | High for complex 3D shapes, but changes are costly |

| Surface Finish & Integrity | Excellent, with no internal porosity | Can have surface imperfections or internal voids |

| Minimum Order Quantity | More flexible, suitable for medium to high volume | Often high due to mold cost amortization |

As shown, extruded aluminum provides superior performance in weight and thermal management while offering economic benefits in tooling and flexibility.

Specific Applications in Material Handling and Forklifts

The unique benefits of extruded housings make them ideal for various demanding roles within a forklift's electrical system.

Primary Drive Motor Housing

This is the core application for a forklift extruded motor housing. It houses the main traction motor, where weight savings translate directly into efficiency gains and longer battery life per charge in electric forklifts.

Hydraulic Pump Motor Enclosure

The motor powering the hydraulic system for lifting and steering also benefits from a lightweight, cooling-optimized aluminum motor case. Efficient heat dissipation ensures consistent hydraulic performance and prevents fluid overheating.

Accessory and Auxiliary Motor Housings

Smaller motors for power steering, cooling fans, or compressors can utilize compact, lightweight aluminum motor shells to reduce overall vehicle weight and improve reliability.

Advantages for Electric Forklift Designs

With the industry shift towards electrification, the role of the extruded motor housing for electric forklifts becomes even more critical. Reducing the weight of non-payload components allows for either a larger battery capacity or a heavier load, addressing key challenges in electric vehicle design [2].

Industry Standards and Quality Assurance

For manufacturers like Jingjiang Hetai Motor Parts Manufacturing Co., Ltd., adherence to international standards is non-negotiable. The company's certification to the ISO9001 quality management system ensures consistent processes and product quality. Furthermore, possessing independent surface treatment qualifications and environmental permits guarantees that products like the successfully developed YX3 profile case meet both performance and regulatory requirements for a global clientele, which includes leading names in the motor and material handling industry.

Future Trends and Innovations

The future of forklift extruded motor housing design is focused on integration and advanced performance. Trends include the development of profiles with integrated cooling fins or channels for liquid cooling, hybrid structures that combine extruded sections with other manufacturing techniques, and the use of even higher-strength alloys to allow for thinner, lighter walls without sacrificing durability. These innovations will continue to push the boundaries of efficiency and power density in material handling equipment.

The forklift extruded motor housing is far more than a simple protective cover; it is a strategically engineered component that significantly impacts the efficiency, performance, and reliability of material handling equipment. Its advantages in weight reduction, thermal management, and production economy make it a superior choice over traditional cast housings. For companies seeking a reliable partner in this specialized field, expertise, scale, and commitment to quality—as demonstrated by manufacturers with extensive mold libraries, stringent tolerance control, and relevant certifications—are essential factors in ensuring optimal motor performance and forklift uptime.

Frequently Asked Questions (FAQs)

1. What are the main benefits of an extruded aluminum housing over a cast one for forklifts?

The primary benefits are significant weight reduction (improving energy efficiency and payload), superior heat dissipation (extending motor life), lower mold costs, and greater design flexibility for custom lengths, making it a cost-effective and high-performance solution.

2. How does the weight of an extruded aluminum housing compare to cast iron?

An extruded aluminum housing is dramatically lighter, weighing approximately only one-fifth of a comparable cast iron housing. This weight saving is a major advantage for electric forklift battery life and overall efficiency.

3. Can extruded housings be customized for different motor sizes and specs?

Yes, customization is a key strength. Manufacturers like Hetai maintain over 600 different shell molds for specifications from 46mm to 260mm inner diameters. The extrusion process allows for easy customization of housing length while using the same cost-effective die.

4. What quality certifications should I look for in a motor housing supplier?

Critical certifications include ISO9001 for quality management systems. Additionally, suppliers with in-house surface treatment qualifications (like anodizing and electrophoresis) and environmental permits demonstrate a controlled, professional production process that ensures consistent quality and durability.

5. Are extruded aluminum housings suitable for high-vibration environments like forklifts?

Absolutely. The combination of high-strength aluminum alloys and the seamless structure created by the extrusion process results in a housing with excellent mechanical integrity and fatigue resistance, making it well-suited to withstand the constant vibrations and shocks experienced in material handling applications [1].

References

[1] Davis, J. R. (Ed.). (1993). Aluminum and Aluminum Alloys. ASM International. (Reference regarding aluminum's properties for vibration and shock resistance).

[2] G. A. (2018). Electric Vehicle Systems and Components. Society of Automotive Engineers. (Reference discussing weight optimization strategies in electric vehicle design, including material handling equipment).

English

English Español

Español