In the intricate world of micro motors—powering everything from precision medical devices to efficient automotive systems—the micro motor shell plays a pivotal role far beyond being a simple housing. It is the cornerstone of thermal management, structural integrity, and long-term performance. Selecting the optimal shell is a critical engineering decision that balances material properties, manufacturing precision, and application demands. This comprehensive guide delves into the core aspects of micro motor shells, empowering design engineers and procurement specialists with the knowledge to make informed choices.

Understanding the Micro Motor Shell: More Than Just a Cover

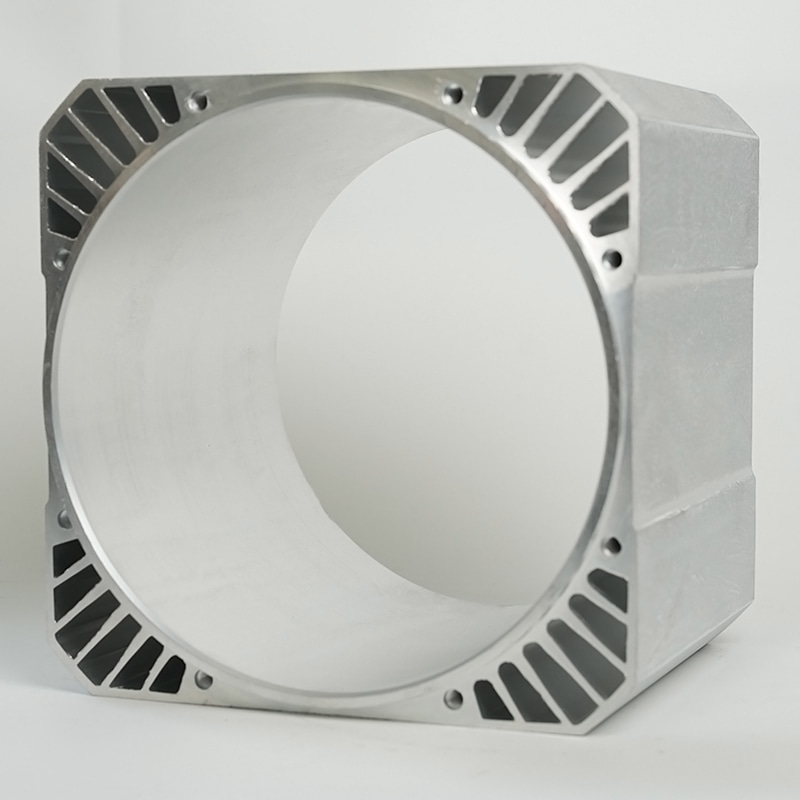

A micro motor shell, also known as a frame or housing, is the outer structure that encloses and protects the internal components of a micro motor, including the stator, rotor, and bearings. Its primary functions are multifaceted:

- Mechanical Protection: Shields delicate internal parts from physical damage, dust, and contaminants.

- Heat Dissipation: Acts as a heat sink, transferring operational heat away from the windings and core to prevent overheating and efficiency loss.

- Structural Support: Provides precise alignment for bearings and internal assemblies, ensuring smooth operation and reducing vibration.

- Electromagnetic Shielding: In some designs, it can help contain electromagnetic interference (EMI).

Companies like Jingjiang Hetai Motor Parts Manufacturing Co., Ltd., with over 17 years of specialization, understand that excellence in these functions begins with material selection and precision manufacturing, forming the foundation for reliable motor performance across industries from automotive to automation.

Key Materials for Micro Motor Shells: A Comparative Analysis

The choice of material directly impacts the motor's weight, cooling efficiency, cost, and durability. The most common materials are aluminum alloy and cast iron, each with distinct advantages.

Aluminum Alloy Shells

Aluminum alloy has become the preferred choice for many modern micro motor shell applications due to its superior strength-to-weight ratio and thermal properties.

- Lightweight: Significantly reduces the overall weight of the motor assembly, crucial for portable devices and automotive applications.

- Excellent Thermal Conductivity: Dissipates heat rapidly, leading to lower operational temperature rises and enhanced motor efficiency and lifespan.

- High Versatility and Cost-Effectiveness: As evidenced by Jingjiang Hetai's expertise, aluminum shells offer low mold cost and strong versatility. For instance, a single pair of molds can produce shells for varying frame lengths, allowing for highly customizable and economical production runs.

- Surface Treatment Options: Can be easily anodized or electrophoresed for improved corrosion resistance and aesthetic appeal.

Cast Iron Shells

Cast iron, a traditional material, is known for its robustness and dampening characteristics.

- Superior Damping: Effectively absorbs vibration and reduces operational noise.

- High Rigidity and Strength: Provides exceptional structural integrity in high-stress, high-torque applications.

- Lower Material Cost: Often has a lower raw material cost compared to aluminum alloys.

Material Comparison Table

| Property | Aluminum Alloy Shell | Cast Iron Shell |

| Weight | Very Light (≈1/5th of equivalent cast iron) | Very Heavy |

| Heat Dissipation | Excellent | Poor |

| Vibration Damping | Moderate | Excellent |

| Production Flexibility | High (Easy to customize length, no internal hole machining often needed) | Low (Requires machining, less flexible) |

| Typical Cost Driver | Material & Surface Treatment | Machining & Weight |

The table clearly illustrates that while cast iron offers better damping, aluminum alloy excels in heat dissipation, weight reduction, and production flexibility, making it ideal for applications where efficiency, size, and customization are priorities [1].

Precision Manufacturing and Quality Control

The theoretical benefits of a material can only be realized through precision manufacturing. This is where expertise in processes like deep drawing and strict quality control becomes paramount. A critical aspect often overlooked is controlling ellipticity in motor shell inner holes. Excessive ellipticity can lead to misalignment, increased vibration, bearing wear, and premature motor failure.

- Tight Tolerances: Leading manufacturers control inner hole ellipticity within extremely tight limits. For example, Jingjiang Hetai maintains ellipticity within 10 seconds of arc, ensuring perfect concentricity for bearing seats.

- Advanced Tooling: Utilizing a vast library of molds (over 600 different specifications and shapes) allows for the production of shells with inner holes ranging from 46mm to 260mm without the need for costly internal machining.

- Integrated Certification: Adherence to international standards like ISO 9001 guarantees a consistent and reliable manufacturing process from raw material to finished shell.

Furthermore, understanding the impact of shell design on micro motor heat dissipation is crucial. An optimally designed aluminum shell features integrated cooling fins or a shape that maximizes surface area, actively channeling heat away. This design-focused approach directly correlates with a lower motor temperature rise and enhanced longevity [2].

Selecting the Right Shell for Your Application

Choosing a micro motor shell is not a one-size-fits-all process. It requires a detailed analysis of the motor's operational environment and performance requirements.

For High-Speed and Precision Applications

Applications like servo motors and spindle drives demand the utmost precision and minimal rotational inertia.

- Priority on Precision: Shells with ultra-tight inner hole tolerances (ellipticity control) are non-negotiable to ensure balance and high-speed stability.

- Material Choice: Aluminum alloy is typically preferred for its lightweight nature, which contributes to faster acceleration/deceleration and better dynamic response.

- Cooling Design: Effective integrated cooling is essential to manage heat from high-speed operation.

For Harsh Environment and High Torque Applications

Motors in automotive, pumping, and lifting systems often face challenging conditions.

- Durability and Sealing: The shell must provide robust protection against moisture, chemicals, and particulate matter. This often necessitates specialized surface treatments like thick electrophoretic coating.

- Structural Rigidity: While aluminum is strong, certain very high-torque applications might benefit from the inherent rigidity of cast iron or specially reinforced aluminum designs.

- Thermal Management: Even in harsh environments, efficient heat dissipation remains critical to prevent insulation breakdown.

When sourcing, it's vital to consider cost-effective sourcing for custom aluminum motor housings. Partnering with a manufacturer that offers extensive mold libraries and flexible production can significantly reduce unit cost and lead time for custom or medium-volume orders.

The Future and Innovation in Motor Shell Technology

The evolution of the micro motor shell continues, driven by demands for higher efficiency, miniaturization, and smarter integration.

- Advanced Materials: Research into metal matrix composites and high-conductivity alloys promises even better thermal and mechanical performance.

- Integrated Functional Design: Future shells may incorporate sensor mounts, connector interfaces, or built-in cooling channels as standard, reducing assembly complexity.

- Sustainable Manufacturing: The focus is increasing on using recycled aluminum and optimizing production processes to minimize energy consumption and waste, aligning with global environmental goals [3].

For engineers working on next-generation projects, such as design considerations for lightweight servo motor enclosures, the synergy between advanced aluminum alloys, topological optimization software for weight reduction, and additive manufacturing for complex geometries represents the cutting edge of enclosure design.

The micro motor shell is a critical, engineered component that directly influences the performance, reliability, and efficiency of the entire motor system. The shift towards aluminum alloy shells, championed by specialized manufacturers, underscores the industry's drive towards lightweight, efficient, and customizable solutions. By understanding the nuances of material properties, the importance of precision manufacturing metrics like ellipticity control, and the specific demands of your application—from servo systems to automotive pumps—you can make a selection that ensures optimal motor performance and longevity. Partnering with an experienced and certified manufacturer provides not just a component, but a foundation for success.

Frequently Asked Questions (FAQs)

1. What are the main advantages of choosing an aluminum alloy shell over a traditional cast iron one?

The primary advantages are significant weight reduction (approximately 80% lighter), superior heat dissipation leading to cooler motor operation, and greater production flexibility which allows for cost-effective customization of dimensions without extensive machining.

2. Why is controlling the ellipticity of the inner hole so important in a micro motor shell?

Controlling inner hole ellipticity is crucial for ensuring precise bearing alignment. Low ellipticity (e.g., within 10 arc-seconds) minimizes vibration, reduces noise, prevents uneven bearing wear, and extends the overall service life of the motor.

3. How does the shell design actually affect the heat dissipation of a micro motor?

The shell acts as the primary heat sink. An effective design uses materials with high thermal conductivity (like aluminum) and maximizes surface area through fins or specific shapes. This pulls heat away from the stator windings more efficiently, lowering the operational temperature rise and preventing insulation degradation.

4. What should I look for when sourcing custom aluminum housings to ensure they are cost-effective?

Look for a manufacturer with a large existing mold library to avoid high upfront tooling costs, one that offers flexibility in production lengths without per-unit machining, and one with integrated surface treatment capabilities. This streamlined approach, as seen in vertically oriented specialists, typically offers the best value.

5. Are aluminum alloy shells suitable for high-torque or harsh environment applications like automotive motors?

Yes, modern aluminum alloys, when properly engineered with adequate wall thickness and reinforced structures, offer excellent strength for high-torque applications. Furthermore, advanced surface treatments like anodizing or electrophoresis provide exceptional corrosion and chemical resistance, making them well-suited for harsh environments.

References

[1] Gieras, J. F. (2010). *Advancements in Electric Motor Design and Materials*. This source provides a comparative analysis of material properties, including thermal and mechanical characteristics, relevant to motor housing selection.

[2] Hendershot, J. R., & Miller, T. J. E. (2010). *Design of Brushless Permanent-Magnet Machines*. This text discusses the thermal management strategies in electric motor design, emphasizing the role of the housing in heat transfer.

[3] International Aluminum Institute. (2023). *Sustainable Aluminum Production and Recycling Initiatives*. This reference highlights industry trends towards sustainable material sourcing and manufacturing processes, informing the discussion on future innovations.

English

English Español

Español