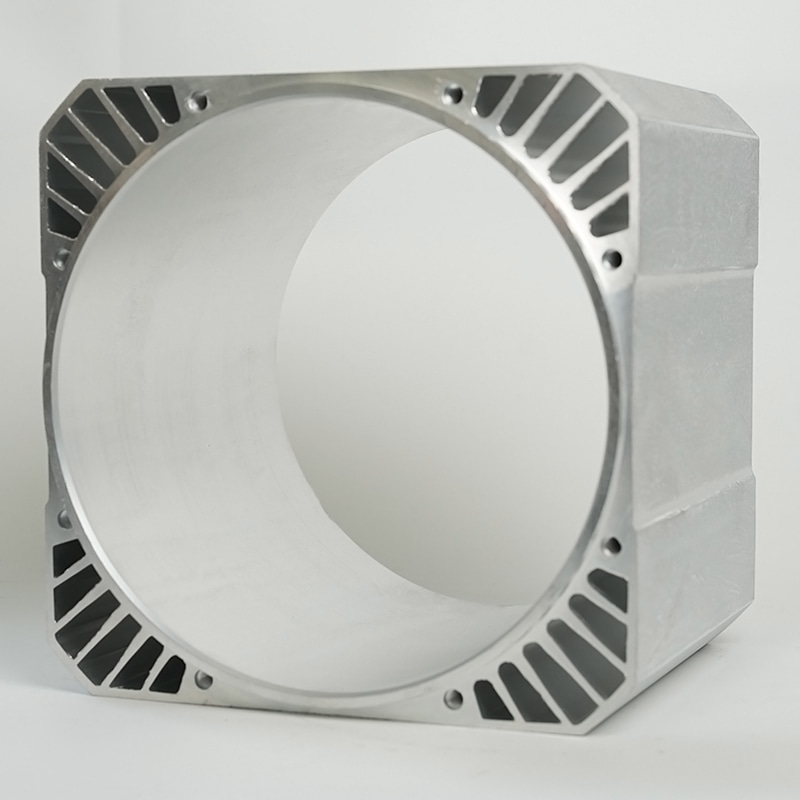

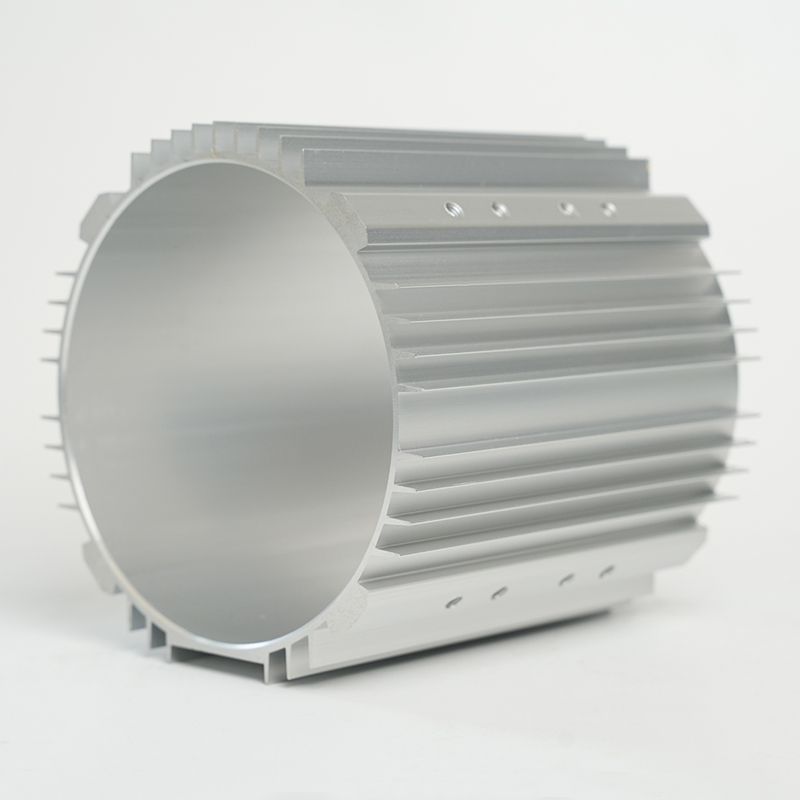

The choice of frame material is critical in modern engineering, particularly for motor housings and industrial equipment. The Aluminum Alloy Frame has become increasingly popular due to its lightweight, thermal efficiency, corrosion resistance, and precision manufacturing capabilities. Jingjiang Hetai Motor Parts Manufacturing Co., Ltd., established in 2007, specializes in high-volume production of aluminum alloy motor shells and components, serving a wide range of applications including reducer motors, sewing machine motors, water pump motors, air conditioning motors, servo motors, and automobile micro-motors.

According to the latest report by ASTM International, aluminum alloy adoption in motor housings increased by 18% between 2023 and 2024 due to improved thermal management and lightweight advantages in industrial applications.

Source: ASTM International

Aluminum Alloy Frame motor housing benefits

The Aluminum Alloy Frame motor housing benefits include versatility in manufacturing, modularity, and adaptability to high-volume production. Unlike wooden frames, aluminum frames resist moisture and biological degradation. Compared to steel, aluminum frames are lighter and offer better heat dissipation.

| Criterion | Aluminum Alloy Frame | Steel Frame | Wooden Frame |

| Moisture & Biological Stability | Excellent resistance | Good (requires coating) | Poor |

| Manufacturing Precision | High (tight tolerance) | Medium | Low |

| Weight | Low | High | Medium |

Aluminum Alloy Frame thermal performance vs steel and wooden frames

Thermal performance is a key factor for motor housings. Aluminum has significantly higher thermal conductivity than steel, facilitating efficient heat dissipation in high-load applications. Wooden frames, by contrast, act as thermal insulators, unsuitable for heat-sensitive components.

| Property | Aluminum Alloy Frame | Steel Frame | Wooden Frame |

| Thermal Conductivity (W/m·K) | ~200+ | ~50 | Very low |

| Heat Dissipation | Efficient | Moderate | Poor |

Source: ASME Thermal Material Analysis

Aluminum Alloy Frame corrosion resistance in motors vs steel and wood

Corrosion resistance is crucial for long-term reliability. Aluminum naturally forms a protective oxide layer that shields against moisture and environmental chemicals. Steel requires additional treatments to prevent rust, while wooden frames degrade biologically and absorb water over time.

| Environment | Aluminum Alloy Frame | Steel Frame | Wooden Frame |

| Humidity Exposure | Excellent | Needs coating | Absorbs water & decays |

| Salt/Industrial Atmosphere | High resistance | Corrodes without protection | Structural decay |

Source: ISO Corrosion Standards

Lightweight Aluminum Alloy Frame engineering applications

Aluminum alloys have a low density (~2.7 g/cm³), offering a weight advantage over steel (~7.85 g/cm³). This weight reduction improves motor efficiency, reduces energy consumption, and simplifies handling during assembly. Wood is lighter than steel but lacks mechanical stability and precision.

| Material | Density (g/cm³) | Engineering Benefit |

| Aluminum Alloy Frame | ~2.7 | Lightweight, efficient, high performance |

| Steel Frame | ~7.85 | High strength, heavier |

| Wooden Frame | ~0.6–0.9 | Light but low precision and durability |

Aluminum Alloy Frame manufacturing tolerances and precision

Precision is vital for motor assembly. Jingjiang Hetai controls inner hole ellipticity within tight tolerances, supporting reliable performance in high-speed motors. Steel machining is slower and more labor-intensive, and wood lacks repeatable precision.

| Manufacturing Aspect | Aluminum Alloy Frame | Steel Frame | Wooden Frame |

| Tolerance Achievability | High | Medium | Low |

| Machining Speed | Fast | Slower | Fast but low precision |

| Surface Finish | Smooth, oxidation-ready | Requires post-processing | Rough |

The Aluminum Alloy Frame combines low weight, thermal efficiency, corrosion resistance, and precise manufacturing, making it ideal for industrial and motor applications. While steel provides higher absolute strength and wood may be suitable for non-technical uses, aluminum alloys meet modern engineering demands with greater versatility and efficiency. Jingjiang Hetai Motor Parts Manufacturing Co., Ltd. continues to advance production capabilities, offering over 600 mold variations and high-volume output with stringent quality control.

Frequently Asked Questions (FAQ)

- Q1: What are the primary advantages of an Aluminum Alloy Frame over steel or wood?

A: An Aluminum Alloy Frame offers significant weight reduction, enhanced thermal conductivity, corrosion resistance, and high manufacturing precision. These properties improve motor efficiency, reduce energy consumption, and ensure long-term durability compared to steel or wooden frames.

- Q2: How does Aluminum Alloy Frame thermal performance vs steel affect motor operation?

A: The high thermal conductivity of an Aluminum Alloy Frame thermal performance vs steel allows heat to dissipate more effectively, reducing temperature rise in motor housings and maintaining optimal performance under high-load conditions. Steel frames dissipate heat more slowly, and wooden frames act as insulators, which may cause overheating.

- Q3: Why is Aluminum Alloy Frame corrosion resistance in motors important?

A: Corrosion resistance in Aluminum Alloy Frame corrosion resistance in motors ensures longevity and reduces maintenance. Aluminum naturally forms a protective oxide layer, preventing rust and chemical degradation, unlike steel that needs coatings or wood which degrades biologically in humid or industrial environments.

- Q4: In what engineering applications does Lightweight Aluminum Alloy Frame engineering applications provide the greatest benefit?

A: Applications requiring high mobility, energy efficiency, or rapid heat dissipation, such as reducer motors, sewing machine motors, water pump motors, and automobile micro-motors, benefit most from Lightweight Aluminum Alloy Frame engineering applications. The reduced weight allows for easier handling and improved overall system efficiency.

- Q5: How do Aluminum Alloy Frame manufacturing tolerances and precision influence assembly quality?

A: Tight control over Aluminum Alloy Frame manufacturing tolerances and precision ensures consistent dimensions, minimal ellipticity in motor housings, and smooth assembly. This reduces vibration, wear, and operational failures, which is critical in high-speed motors and industrial applications compared to steel or wooden alternatives.

English

English Español

Español