In the demanding world of material handling and industrial machinery, the motor housing is a critical component that ensures reliability, efficiency, and longevity. Among various manufacturing techniques, the forklift extruded motor housing stands out for its unique blend of performance and practicality. This guide delves deep into the specifics of extruded aluminum housings, exploring their design principles, key benefits, and why they are increasingly becoming the preferred choice for modern forklift motors and other specialized applications.

Understanding Extruded Aluminum Motor Housings

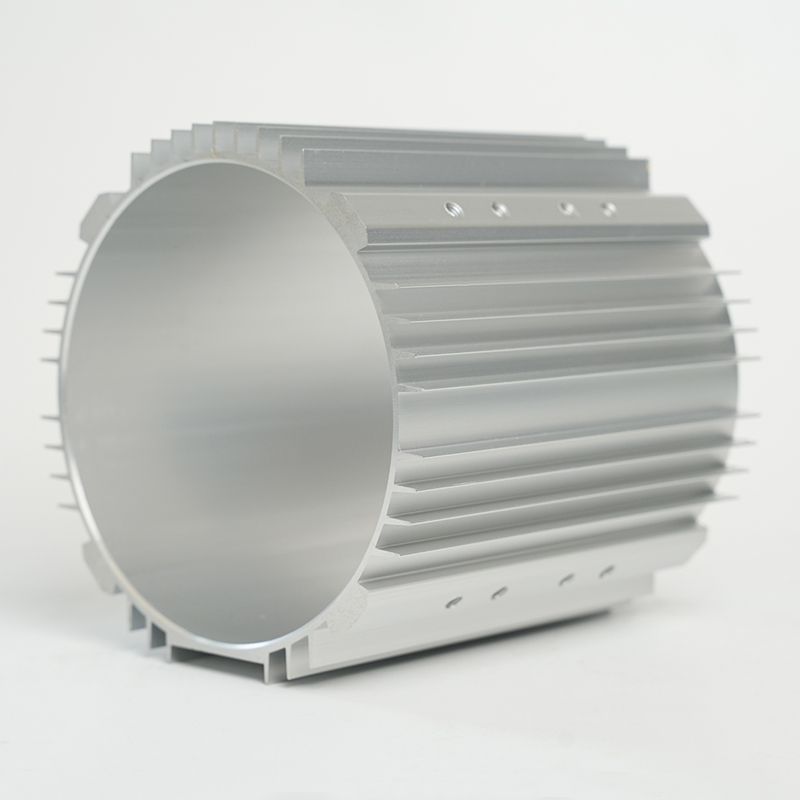

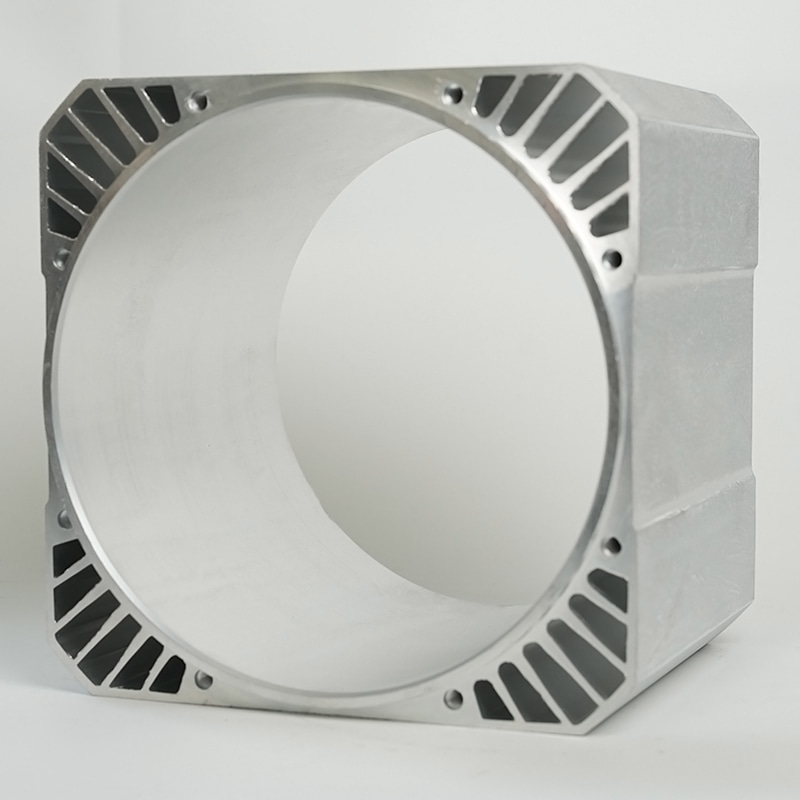

Extrusion is a manufacturing process where aluminum alloy is forced through a die to create long profiles with a consistent cross-sectional shape. This method is particularly suited for producing motor housings, as it allows for precise, complex geometries that are both strong and lightweight. For companies like Jingjiang Hetai Motor Parts Manufacturing Co., Ltd., with over 15 years of expertise and a vast library of over 600 different shell molds, extrusion enables the production of highly customized aluminum alloy motor cases for servo systems and other micro-special motors with exceptional consistency and quality control.

Key Characteristics of the Extrusion Process

Precision and Consistency

- The process yields housings with excellent dimensional accuracy.

- Inner hole ellipticity can be tightly controlled within 10 seconds, a critical tolerance for proper motor assembly and function.

- Allows for mass production with class outputs reaching up to 5,000 sets.

Design Flexibility

- Creates integrated structures with intricate cooling fins and mounting features.

- Eliminates the need for secondary machining for internal holes in many cases.

- Enables easy customization of length and specific features to meet exact OEM requirements.

Advantages of Forklift Extruded Motor Housings

Choosing an extruded aluminum housing over traditional cast iron or steel alternatives offers a multitude of operational and economic benefits. These advantages directly address the core needs of forklift manufacturers and operators seeking durability, efficiency, and cost-effectiveness.

Superior Thermal Management

Effective heat dissipation is paramount for motor longevity and consistent performance. Extruded aluminum housings excel in this area. The nature of the extrusion process allows for the integration of optimized, thin-walled cooling fins that significantly increase the surface area for heat transfer. When comparing thermal performance, the difference is clear. An extruded aluminum housing facilitates rapid heat dissipation, leading to lower operational temperature rise, whereas a traditional cast iron housing has slower heat dissipation, often resulting in a higher temperature rise under the same load. This inherent capability makes it an excellent choice for high torque forklift motor enclosures that frequently operate under strenuous conditions.

Lightweight Durability

Aluminum alloys provide an exceptional strength-to-weight ratio. A key advantage is the significant reduction in overall weight. For instance, a pair of aluminum alloy tensile shells weighs only about one-fifth of a comparable cast iron shell. This weight saving translates directly into enhanced energy efficiency for the forklift, allowing for longer battery life or reduced fuel consumption. Despite being lighter, the structural integrity is not compromised, offering robust protection for the internal motor components against impacts and environmental factors.

Cost-Effectiveness and Versatility

The economic benefits are compelling, especially for manufacturers. The mold cost for extrusion is considerably lower than for casting complex shapes. Furthermore, a single extruded profile can often serve multiple motor frame sizes. A prime example is the versatility mentioned by industry leaders: a single pair of molds can produce housings for both 132M and 132L frame motors, with the length customized as needed. This lightweight aluminum motor casing for electric forklifts reduces not only material costs but also inventory and logistics complexity for both producers and their clients.

Critical Applications Beyond Forklifts

While the focus is on forklifts, the utility of precision extruded housings extends far beyond. The inherent advantages make them suitable for a wide array of motors requiring reliability and efficient performance. Jingjiang Hetai's products, for example, are widely used in reducer motors, sewing machine motors, pump motors, and automotive motors. The development of profiles like the YX3 series from 71 to 160 bases underscores their commitment to serving diverse industrial needs.

Servo and Specialized Motor Systems

For high-precision applications such as servo motors, the stability and precision of the housing are non-negotiable. An extruded aluminum motor case for servo systems provides the exacting tolerances and consistent quality required for these sensitive devices, ensuring minimal vibration and optimal alignment.

Pump and Compressor Motors

Motors operating pumps and compressors benefit greatly from the enhanced cooling of extruded housings, which helps manage the heat generated during continuous duty cycles, thereby improving reliability and service life.

Material and Manufacturing Excellence

The quality of the final product is inextricably linked to the materials used and the manufacturing rigor applied. Reputable manufacturers adhere to stringent standards throughout the production process.

Aluminum Alloy Selection

High-grade aluminum alloys are chosen for their optimal blend of:

- Machinability

- Thermal conductivity

- Corrosion resistance

- Structural strength

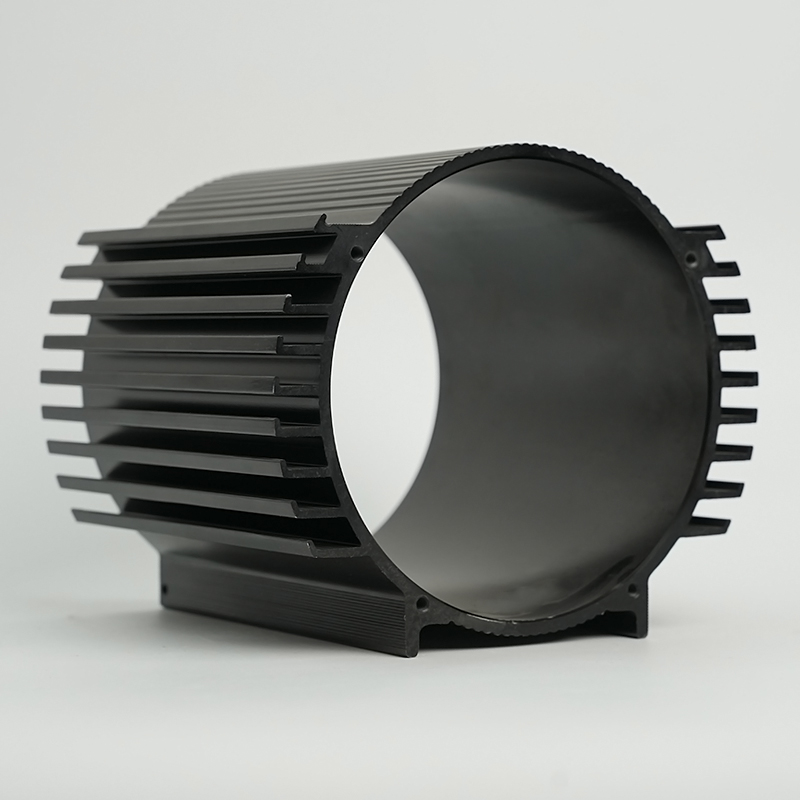

Advanced Production and Finishing

Comprehensive capabilities define a top-tier supplier. Facilities with in-house surface treatment, such as anodizing and electrophoresis, ensure superior corrosion resistance and aesthetic finish. Furthermore, possessing environmental permits reflects a commitment to sustainable manufacturing. The ability to produce a durable extruded housing for warehouse equipment motors relies on this end-to-end control over the production process, from billet to finished, treated component.

Choosing the Right Supplier for Extruded Motor Housings

Selecting a manufacturing partner is a strategic decision. Key factors to consider include technical capability, quality assurance, and production flexibility. The ideal partner offers a combination of experience, a broad mold inventory for custom forklift motor housing designs, and certified quality systems like ISO 9001, which Jingjiang Hetai Motor Parts Manufacturing Co., Ltd. has achieved. Their collaboration with numerous domestic and international enterprises stands as a testament to their capability in delivering parts that meet diverse and demanding specifications.

Comparative Analysis: Key Decision Factors

When evaluating potential suppliers for your motor housing needs, several critical factors come into play. The following comparison highlights what to look for:

| Decision Factor | Advantageous Supplier Profile | Potential Risk Profile |

| Technical & Mold Capability | Extensive mold library (600+), ability to develop new profiles (e.g., YX3 series), in-house design support. | Limited standard options, no custom design service, long lead times for new molds. |

| Quality & Certification | ISO 9001 certified, tight tolerance control (e.g., 10s ellipticity), in-house surface treatment with proper permits. | No formal quality certification, inconsistent dimensional accuracy, outsourcing of critical finishing steps. |

| Production Scale & Flexibility | Large-scale capacity (5,000 sets/class), ability to customize lengths and batches, versatile production lines. | Limited batch sizes, inflexible minimum order quantities, long changeover times. |

| Industry Experience & Clientele | Proven track record with reputable OEMs in forklift, automotive, and industrial motor sectors. | Limited or no references from major industrial clients, focus on commoditized products. |

Frequently Asked Questions (FAQ)

1. What are the primary benefits of an extruded motor housing over a cast one for forklifts?

The primary benefits are superior heat dissipation due to integrated cooling fins, a drastic reduction in weight (approximately 80% lighter than cast iron), lower mold costs, and greater design flexibility for customization, making it ideal for high torque forklift motor enclosures.

2. How does the weight of an aluminum extruded housing impact forklift performance?

The reduced weight decreases the overall mass of the forklift, leading to improved energy efficiency. This results in extended battery life for electric models, lower fuel consumption for internal combustion models, and can contribute to increased payload capacity.

3. Can extruded aluminum housings be customized for specific motor designs?

Yes, a key advantage is high customizability. Reputable manufacturers like Jingjiang Hetai offer custom forklift motor housing designs with varying lengths, mounting configurations, and fin geometries. Their vast mold inventory allows for efficient production of both standard and bespoke profiles.

4. Are extruded aluminum motor housings durable enough for rugged warehouse environments?

Absolutely. High-strength aluminum alloys combined with robust extrusion designs create a durable extruded housing for warehouse equipment motors. They provide excellent resistance to impact and corrosion, especially when finished with treatments like anodizing or electrophoresis.

5. What applications beyond forklifts are suitable for these housings?

Their excellent thermal and mechanical properties make them suitable for a wide range of applications, including servo motors, pump motors, compressor motors, and automotive auxiliary motors. Essentially, any application requiring a lightweight aluminum motor casing for electric forklifts or other equipment with efficient cooling and reliable performance is a candidate.

English

English Español

Español