In the demanding world of material handling and industrial machinery, the performance and reliability of core components are paramount. The motor, as the heart of a forklift, requires robust protection and efficient thermal management to ensure longevity and consistent power output. This is where the forklift extruded motor housing plays a critical role. Unlike traditional casting methods, extrusion offers a unique set of advantages for creating durable, lightweight, and highly efficient protective casings for motors. This comprehensive guide delves into the specifics of extruded aluminum housings, their benefits for forklift applications, and key considerations for selection, drawing on the expertise of specialized manufacturers like Jingjiang Hetai Motor Parts Manufacturing Co., Ltd.

Understanding Forklift Extruded Motor Housing

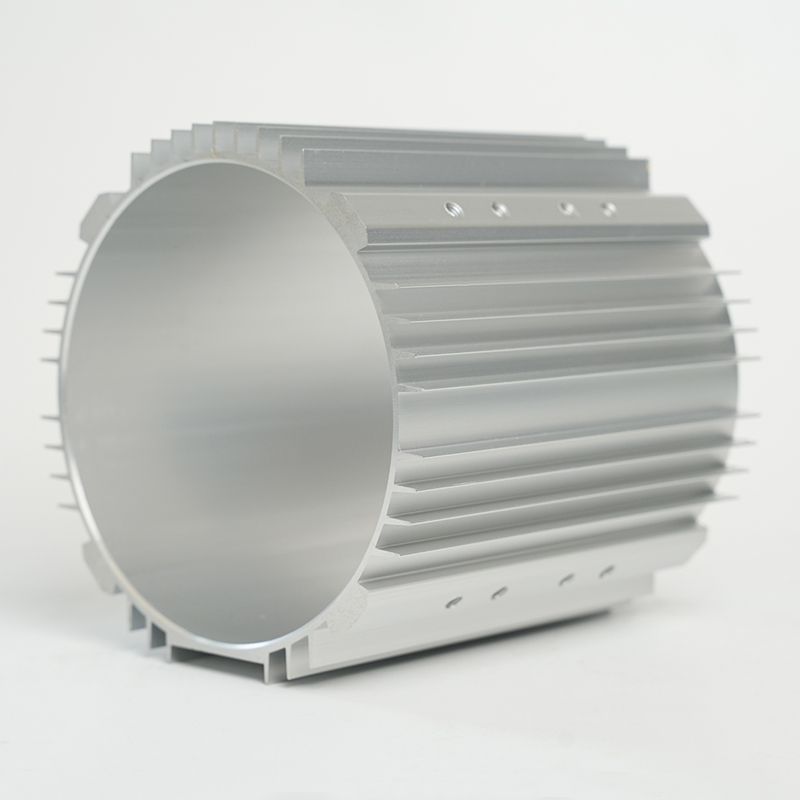

An extruded motor housing is precisely crafted by forcing heated aluminum alloy through a shaped die to create a continuous profile. This manufacturing process allows for the production of seamless, high-strength tubes with complex cross-sectional geometries tailored for specific motor designs. For forklifts, these housings must withstand vibration, impacts, and harsh environmental conditions while effectively dissipating the heat generated by the motor.

Key Characteristics of Extruded Aluminum Housings

- Seamless Structure: The extrusion process creates a one-piece profile, eliminating weak points found in welded or assembled casings.

- Precision Tolerances: Advanced extrusion and machining can control critical dimensions like inner hole ellipticity to within tight specifications.

- Material Consistency: The grain structure of aluminum is improved through extrusion, enhancing its mechanical properties.

Top 5 Advantages of Choosing Extruded Housings for Forklift Motors

Selecting the right motor housing directly impacts forklift performance, maintenance costs, and operational efficiency. Here’s why extruded aluminum housings are increasingly preferred.

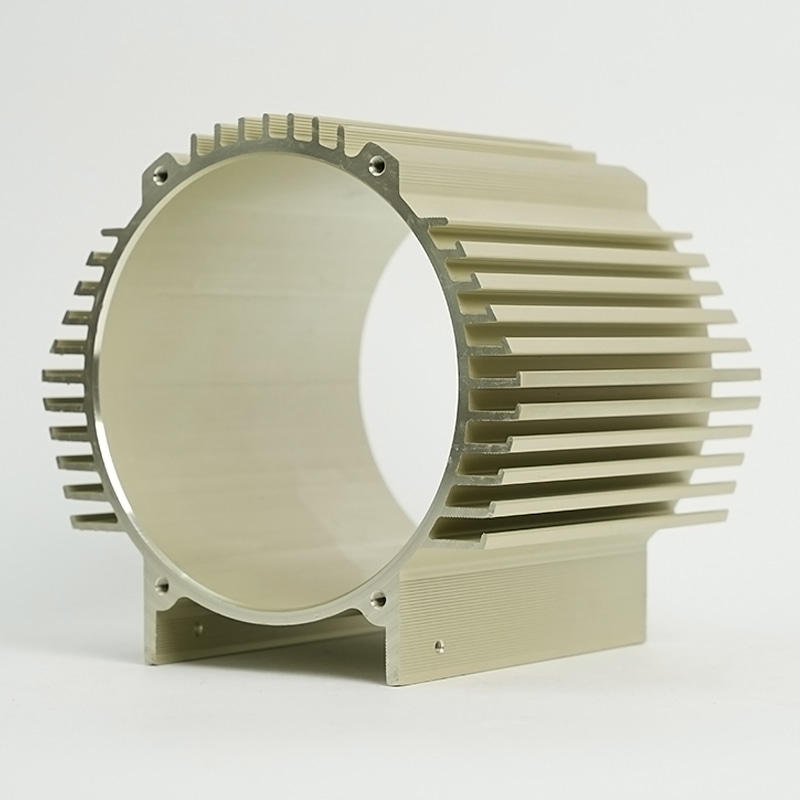

Superior Heat Dissipation and Thermal Management

Aluminum's high thermal conductivity is a primary advantage. An extruded housing acts as a large heatsink, pulling heat away from the motor windings and stator core more effectively than cast iron. This results in a lower operating temperature, which extends insulation life, maintains motor efficiency, and prevents thermal overload[1].

- Reduced Temperature Rise: Directly leads to higher motor efficiency and longer component life.

- Consistent Performance: Prevents power derating in high-duty-cycle applications.

Significant Weight Reduction and Fuel Efficiency

The density of aluminum is approximately one-third that of cast iron. This dramatic weight savings contributes directly to improved forklift dynamics and energy consumption. A lighter motor assembly reduces the overall vehicle weight, leading to better battery life in electric models or lower fuel consumption in internal combustion models.

A comparison of housing material properties highlights the difference:

| Property | Extruded Aluminum Alloy | Cast Iron |

|---|---|---|

| Density | ~2.7 g/cm³ | ~7.2 g/cm³ |

| Thermal Conductivity | High | Low |

| Typical Weight for Comparable Housing | ~1/5 of Cast Iron | Base Weight |

| Impact on Vehicle Payload | Increases available capacity | Reduces available capacity |

Enhanced Design Flexibility and Customization

The extrusion process supports a vast array of profiles. This allows manufacturers like Jingjiang Hetai to offer housings with inner holes ranging from 46mm to 260mm and maintain a library of over 600 different mold specifications. This flexibility enables custom extruded motor housing for special applications, ensuring a perfect fit for various motor frames, from servo to pump motors.

- Tailored Lengths: Housing length can be customized arbitrarily without new mold costs for the same series.

- Integrated Features: Cooling fins, mounting brackets, and conduit openings can be incorporated into the extruded profile.

Cost-Effectiveness in Production and Machining

While tooling requires an initial investment, extrusion offers long-term cost savings. A single mold set can often produce housings for multiple motor lengths within the same frame size (e.g., 132M and 132L), reducing per-unit mold cost. Furthermore, the extruded aluminum housing manufacturing process produces near-net-shape parts that require minimal secondary machining, saving both time and labor.

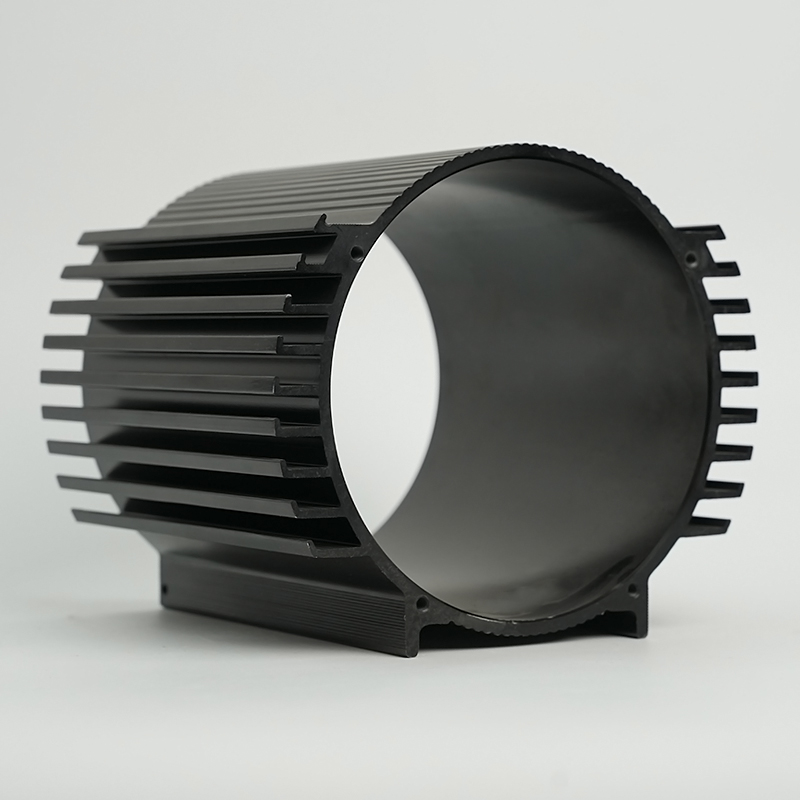

Exceptional Corrosion Resistance and Durability

Aluminum naturally forms a protective oxide layer. When combined with surface treatments like anodizing or electrophoresis—processes for which Jingjiang Hetai holds independent qualifications—the housing's resistance to corrosion, chemicals, and moisture is significantly enhanced. This is crucial for forklifts operating in damp warehouse environments or around corrosive agents.

Critical Considerations for Selecting Your Motor Housing

Choosing the right housing involves more than just material selection. Several technical and operational factors must be evaluated to ensure optimal performance and value.

Material Grade and Alloy Composition

Not all aluminum alloys are equal. The choice of alloy (e.g., 6061, 6063) affects tensile strength, machinability, and corrosion resistance. The alloy must be selected to balance the mechanical demands of the forklift application with the requirements of the extrusion process.

Precision Machining and Dimensional Tolerances

The housing's interior dimensions are critical for proper motor fit and alignment. High-precision boring is essential to control the inner hole cylindricity and ellipticity. For instance, controlling ellipticity within 10 seconds of arc, as practiced by advanced manufacturers, ensures minimal air gap variance, leading to smoother motor operation and reduced noise. This precision is a key factor when discussing precision boring for forklift motor casings.

Thermal Performance Analysis

For high-performance applications, a detailed thermal analysis should be conducted. This involves evaluating the housing's surface area, fin design (if present), and the thermal interface between the motor stack and the housing wall. Proper design prevents hotspots and ensures even heat distribution.

Structural Integrity and Vibration Resistance

The housing must withstand static loads and dynamic vibrations. The extruded profile's geometry influences its moment of inertia and stiffness. Finite Element Analysis (FEA) can be used to simulate stress points under load, ensuring the housing design meets the rugged demands of durable motor housing for electric forklifts.

Surface Treatment for Longevity

The chosen surface finish directly impacts lifespan. Options include:

- Anodizing: Increases surface hardness and corrosion resistance; allows for color coding.

- Electrophoresis: Provides a uniform, durable organic coating with excellent corrosion and chemical resistance.

- Powder Coating: Offers a thick, decorative, and protective layer.

Optimizing Performance: The Role of Advanced Manufacturing

Partnerships with experienced manufacturers bring tangible benefits to forklift OEMs and motor producers. Jingjiang Hetai Motor Parts Manufacturing Co., Ltd., with its focus on aluminum alloy products since 2007, exemplifies the capabilities required for high-volume, quality production.

High-Volume Production with Consistent Quality

Large-scale manufacturing facilities, capable of outputs like 5,000 sets per class, ensure supply chain reliability. Consistency is maintained through integrated processes from extrusion to final machining and surface treatment, all under a certified ISO9001 quality management system.

Comprehensive In-House Capabilities

Vertical integration, from owning extrusion and surface treatment lines to maintaining a vast mold library, allows for tighter control over quality, lead times, and cost. The successful development of profiles like the YX3 series demonstrates innovation in meeting evolving industry standards.

Meeting Diverse Industry Applications

The versatility of extruded housings is shown in their wide use. The same core manufacturing expertise that produces a forklift extruded motor housing is applicable to motors for reducers, sewing machines, pumps, air conditioning, servos, and automotive applications. This cross-industry experience informs better design for forklift-specific challenges.

Future Trends and Innovations

The evolution of motor housing technology is driven by the needs for higher efficiency, integration, and sustainability.

Integration with New Motor Technologies

As permanent magnet and high-efficiency induction motors become standard, housings must adapt to different heat generation patterns and potentially provide enhanced magnetic shielding. The quest for lightweight aluminum housing for high-torque motors is central to this trend, enabling more power-dense forklift drivetrains.

Sustainability and Recyclability

Aluminum is infinitely recyclable with a fraction of the energy required for primary production. Using extruded aluminum housings supports circular economy goals in industrial equipment manufacturing, reducing the overall carbon footprint of the forklift lifecycle.

Frequently Asked Questions (FAQ)

1. What is the main advantage of an extruded aluminum housing over a cast iron one for forklifts?

The primary advantage is a combination of significant weight reduction (approximately 80% lighter) and superior heat dissipation. This leads directly to improved forklift energy efficiency, greater effective payload capacity, and longer motor life due to lower operating temperatures.

2. Can extruded housings be customized for non-standard motor sizes?

Yes, a key benefit of extrusion is its design flexibility. Manufacturers can create custom die profiles to produce housings for special motor dimensions or integrate specific features like mounting flanges or extended cooling fins, making them ideal for custom extruded motor housing for special applications.

3. How does precision boring affect motor performance?

Precision boring ensures the motor's stator fits perfectly within the housing with a consistent and minimal air gap. This minimizes magnetic losses, reduces vibration and noise, and ensures efficient heat transfer from the stator to the housing, which is a critical aspect of precision boring for forklift motor casings.

4. Are aluminum motor housings durable enough for rough warehouse use?

Absolutely. When made from high-strength aluminum alloys and optionally treated with hard anodizing or similar coatings, they offer excellent durability. Their inherent resistance to corrosion, combined with the structural integrity from the extrusion process, makes them a durable motor housing for electric forklifts and ICE models, capable of withstanding impacts and harsh environments.

5. Why is thermal management so critical in electric forklift motor housings?

Electric forklift motors often operate under frequent start-stop cycles and high torque demands, generating considerable heat. Effective thermal management via a lightweight aluminum housing for high-torque motors prevents insulation degradation, preserves magnet strength (in PM motors), and avoids thermal shutdowns, ensuring reliability and maximizing battery run-time per charge.

References

[1] Knight, A. M., & Miller, T. J. E. (2010). *Thermal Management of Electric Machines*. IET Digital Library. (Reference for the principles of heat dissipation and its impact on motor insulation life and efficiency).

[2] ASM International Handbook Committee. (1990). *Properties and Selection: Nonferrous Alloys and Special-Purpose Materials* (Vol. 2). ASM International. (Reference for material properties of aluminum alloys versus cast iron).

[3] Jain, R. K., & Gupta, K. (2015). *Advanced Manufacturing Processes*. McGraw Hill Education. (Reference for extrusion process capabilities and economic advantages).

English

English Español

Español